Blown vs. Cast Stretch Film: What’s the Difference (and Why It Matters)

Two rolls of stretch film might look identical—until you use them. One feels smooth and clear; the other grips tighter and shrugs off punctures.The difference lies in how they’re made. Blown and cast films each bring unique strengths, and choosing the right one can have a major impact on wrapping consistency, cost, and machine performance. […]

What Is Stretch Film (and Why It’s So Effective)

Old-school shipping relied on straps, shrink wrap, and tape to hold pallets together—but nothing reshaped the packaging world like stretch film.This flexible, high-tension material quietly became the standard for securing, protecting, and presenting pallet loads across every industry. Stretch film is made from linear low-density polyethylene (LLDPE), a tough resin that gives the film both […]

Why Pre-Stretch Matters in Stretch Wrapping

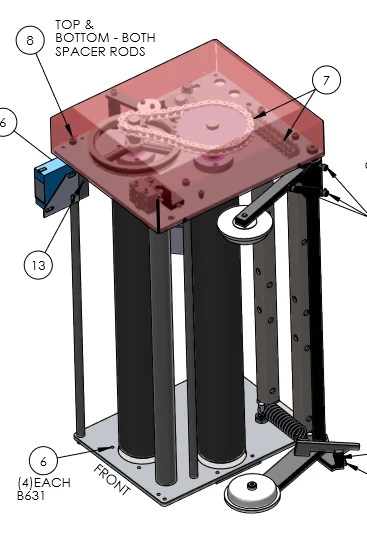

At Nitech IPM, we get asked a lot about what makes our film systems different — and one of the biggest performance factors comes down to pre-stretch. Pre-stretch is exactly what it sounds like: the process of stretching film before it’s applied to a pallet. The film passes through two rollers — the second turning […]

Stretch Film Performance and How to Choose the Right One

Stretch film choice can make the difference between a stable shipment and a pallet that shifts halfway to its destination.Every load is different, and so is every film. Finding the right balance of strength, flexibility, and tension control is key to consistent performance. Nitech IPM helps customers match their film, machine, and load type to […]